The suitability of specific bamboo species for the before mentioned products shall be proved. Furthermore optimal process parameters shall be found, as like crushing (strand geometry) or lamella production (yield, geometry), pressing (time, pressure), thermal treatment (durability), among others. Results shall show mechanical properties (MOE, MOR, internal bond, among others), physical properties (density, sorption behavior, swelling) and possibly practice-related properties (biological durability). The project is divided in four working packages:

I: State of art of engineered bamboo products in emerging countries - composite materials for semi-structural and structural purpose made out of bamboo

II: Technological suitability of bamboo species for the production of structural bamboo composites – special regard to native and exotic species from Brazil (Guadua weberbauerii, Bambusa vulgaris) and Ethiopian highland (Yushania alpina) and lowland bamboo (Oxytenanthera abyssinica)

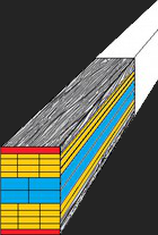

III: Development of a low-tech approach for the production of a SBC using glue-laminated bamboo lamella reinforced with long-stranded bamboo mats

IV: Property improvement by thermal modification (sorption behavior, swelling, durability) – special regard to local climate and technology conditions

I: State of art of engineered bamboo products in emerging countries - composite materials for semi-structural and structural purpose made out of bamboo

II: Technological suitability of bamboo species for the production of structural bamboo composites – special regard to native and exotic species from Brazil (Guadua weberbauerii, Bambusa vulgaris) and Ethiopian highland (Yushania alpina) and lowland bamboo (Oxytenanthera abyssinica)

III: Development of a low-tech approach for the production of a SBC using glue-laminated bamboo lamella reinforced with long-stranded bamboo mats

IV: Property improvement by thermal modification (sorption behavior, swelling, durability) – special regard to local climate and technology conditions